Melt-blown Non-woven Slitter Rewinder Machine GFTW-1600A

$78000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,FCA |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | SHANTOU |

Select Language

$78000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,FCA |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | SHANTOU |

Model No.: GFTW-1600A

Brand: SMF

Applicable Industry: Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Italy, Canada, Egypt, Saudi Arabia, Indonesia, India, Thailand, Uzbekistan, Morocco, Malaysia

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Canada, Turkey, Italy, Viet Nam, Thailand, India, Indonesia, Saudi Arabia, Romania, Morocco, Malaysia

Old And New: New

Species: Slitting Rewinder

Programming Control: Yes

Place Of Origin: China

Warranty Period: 1 Year

Productivity: 200 M/Min

Core Selling Point: Easy To Operate

Max. Feasible Width: 1600mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Core Components: Motor

PLC Brand: Mitsubishi, Siemens, Schneider

Application: Mechinery&Hardware

Type: High-Speed Slitting Machine

Work Method: Flat Knife Slitting

Structure: Frame Part

Packaging Type: Case

Classification: Ultrasonic Label Cutting Machine

Applicable Process: Process Materials

Suitable Substrates: Paper

Packaging Material: Plastic

Rewind Diameter: 600mm

Unwind Diameter: 800mm

Rewind Paper-core: 3-inch

Machine Speed: 250m/min

Whole Machine Power: 380V / 3 Phase, 50Hz About 11KW

Slitting Material: Melt-blown Non-woven Fabric

Effective Width: 200-3400mm

Rewind Width: 50-3400mm

| Selling Units | : | Set/Sets |

| Package Type | : | SEAWORTHY WOODEN OR NAKED |

| Picture Example | : |

|

Melt-blown Non-woven Slitter Rewinder Machine GFTW-16 00

Melt-blown Non-woven Slitter Rewinder Machine GFTW-3400 is mainly for slitting the woven fabric of face mask.

We can make customized according to customer's specific requirements and can provide extensive production analysis to make sure the most efficient design is identified.

1. Function

1.1. Machine has automatic constant tension unwind, taper tension control center to rewind and tension keeping function when machine stop.

1.2. Slitting into suitable harness, length and neatly roll material.

1.3. It has Automatic web guiding function

2. Technical Characteristic

2.1. It adopts SIEMENS man-machine interface, PLC programmable controller, digital module, meanwhile, it adopts YASKAWA AC servo motor drive for rewind, YASKAWA servo motor drive traction to reach dynamic condition automatic control between complete machine line-speed and 3 segments tension. It could achieve soft start and soft stop.

2.2. It adopts taper tension control center and surface rewind type, product surface will not be dragged and abrased or bruised because of the changeable of rolling diameter, which insured the tension uniformity.

2.3. Electric control of complete machine control has 1 control point, and the same command can finish synchronization automatic control among unwind, rewind and 3 segments tension.

2.4. Both Rewind and Unwind are equipped with emergency stop buttons, safe and reliable.

2.5. Whole machine adopts easy operation, easy assemble, easy disassembly, easy maintaining mechanical structure.

3. Main Technical Parameters

3.1. Effective width: 3400mm

3.2. Unwind diameter: 800mm

3.3. Rewind width: 50-3400mm

3.4. Rewind diameter: 600mm

3.5. Rewind paper-core: 3-inch

3.6. Machine speed: 0-250 m/min

3.7. Whole machine power: 380 V / 3phase, 50Hz about 11KW

Company Information:

Sunny Machinery Factory is an integrated professional manufacturer to produce, design and sell Slitting, Rewinding, Laminating, Coating, and CPP or CPE 3 or multiple layers Cast Film machinery facilities with more than 19 years of experiences.

Our company has been developing and moving towards a greater competitive advantage by continuously improving technology and innovation.

All project will be serviced by our expertise in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department, so we can offer our clients with our top standard machinery, also we can make all kinds of modifications according to customer specific requirements.

Our machineries are sold in many countries including India, Indonesia, Thailand, Vietnam, Brazil, Poland, Korea, Italy, Philippines, Singapore, Russia, Malaysia, Pakistan and so on.

Company Introduction

SMF focus on Innovation Research and Develop Leader Specialize in design and manufacture primary and secondary Slitter & Rewinder machine, CPP/CPE Multi-layer Co-Extrusion Casting Film line and Extrusion Lamiante Coating Machine in China Since 1998.

SMF keep Integrity and pragmatic, keep improving, quality first, customer paramountcy. People-oriented, try our best to do our efforts for the customers' satisfaction, with customers and suppliers adhere to the close cooperation between and close interaction

All project will be serviced by our expertise in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department, so we can offer our clients with our top standard machinery, also we can make all kinds of modifications according to customer specific requirements. Outstanding end-to-end service support. Reliable assistance – around the globe, at all times.

You Are Currently Facing The Problem?

A. Without professional technicians, do not know how to choose machine?

B. Do not find the right machine structure to match your currently demand?

C. Found the right machine, but do not have suitable or professional operator to run the lines?

D. No reliable machinery factory can provide a good economic solution for machines?

E. The machinery supplier can not cooperate in time or delivery in time?

F. OEM SERVICE OEM

We have offered OEM service since 1998, and we can make the product with customer`s specific requirements, and can custom the packaging for customer.

We Can Provide You

All project will be serviced by our expertise engineer in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department

We choose the machine structure according to your specific requirements.

We have professional operator dispatch to your esteemed company for training your staff.

We have been served clients all over the world.We offer quotations within 1-3 days and arrange shipment within 90-180 days.

Specialized OEM Services

1. Components

SIMENS, YASKAWA, MITSUBISHI, MITUSHAHI, E+L, JCTIMES, MERO, HIWIN, ABB and so on

2. Color Ivory color, the color is determined by you.

3. Size and shape

According to customer requirement and design drawing for reference

4. LOGO

Metal plate or printing

5. Packaging

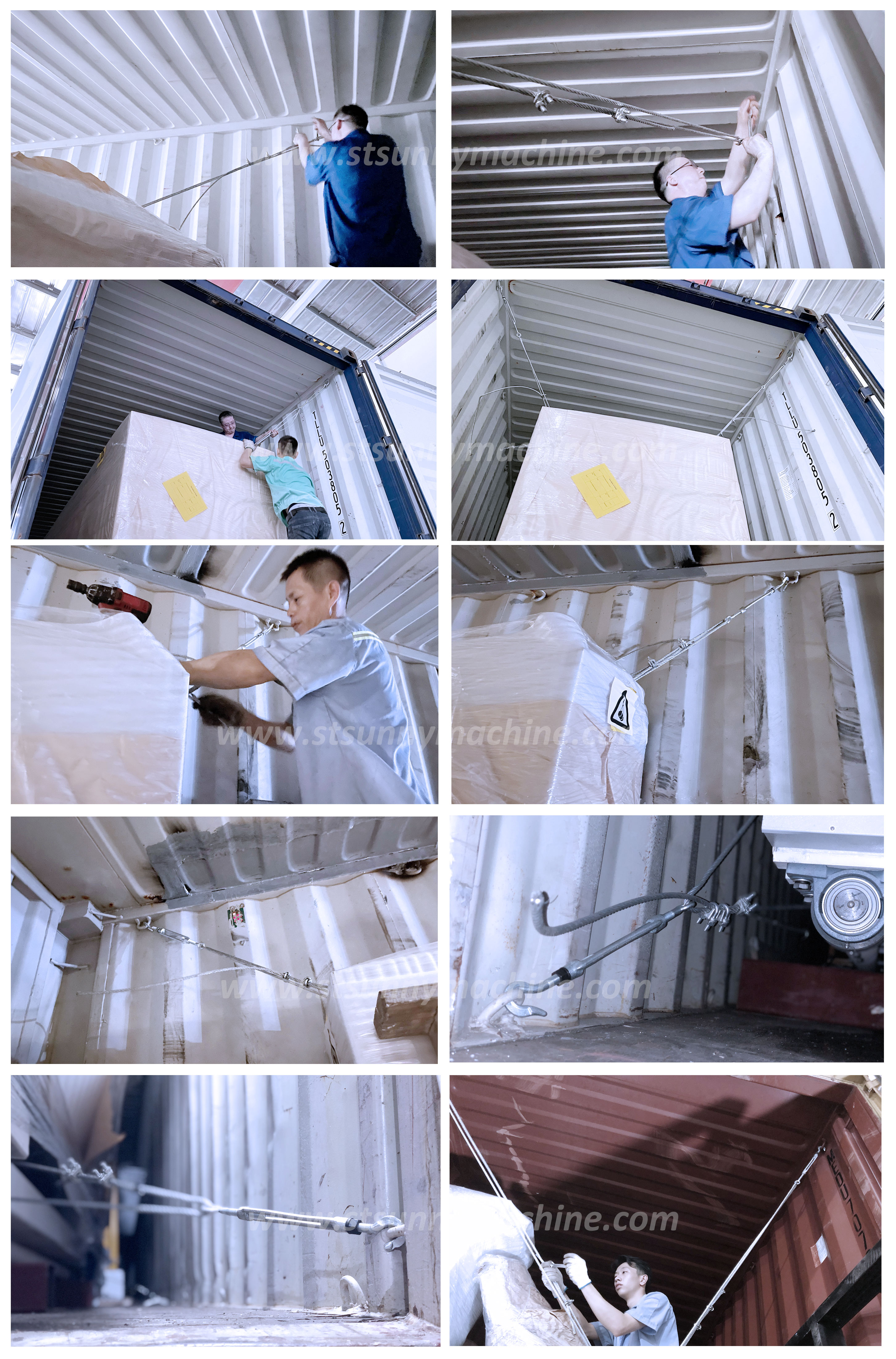

Provide adaptation seaworthy packing, spray antirust paint and reinforce when machine loaded container

CUSTOMIZATION SERVICE

The customer inquire about the certain product according to the demand. After receives the inquiry, we will price the product. Then the corresponding quotation will be sent to the customers according to their request.

Customization process 1

Determine customer needs by meeting, email or telephone. According to the customer`s needs and bargain, we would offer the solution for customer. Our designer will make drawing according to customer needs, or customer shows us what they need, or choose from our available standard machinery.

Customization process 2

According to the solution of first step, our team will prepare drawing accordingly. It includes technical parameters, and all the solutions of machine.

Customization process 3

When everything ready, and after customer finalized project, our team will start to make according to the drawing. Machine production step as below: - requirements finalized by customer – drawing will be provide to customer for confirmation – Initiate to purchase components – assembly in our workshop – any machine processing will be taken photo to customer checking – trial running in our workshop – inform customer come to our factory for official test running acceptance – preparing for shipment – send all documents to customer by DHL

Customization process 4

Our sales team will take photo, videos during loading container and send to customer checking

1. Design

2. Processing

3. Assembly

4. software programming

5. Debugging

6. Shipment

7. Installation

8. After-sale service

Container Loading requirements

1. The goods should not be overweight, dangerous goods are not allowed to be loaded

2. Mechanical goods should be strengthened with 10mm steel wire rope and tied tightly to the container wall (iron wire is not allowed to replace).

3. The bottom of the mechanical goods should be supported by wooden blocks and then fastened to the bottom of the container

4. 10mm and above steel wire rope with 3 lock catch, to secure the goods safely and effectively, will not move back and forth, left and right, up and down to the standard

5. All rollers of machine should be wrapped with film + kraft paper

6. The machine packaging must be divided into four layers: the innermost with wrapping film, the second layer with kraft paper, the third layer with pe foam and the outermost with wrapping film

7. The HMI should be packed well and put into the desiccant

8. 2 bags desiccant shall be put into the electric control cabinet of the machine, each desiccant with 1kg

9. The machine nameplate should be placed on the outermost part of the cabinet, and the place where the nameplate is packaged should be exposed in case custom inspection

10. The exposed parts of the machine must be sprayed with anti-rust paint before shipment

11. All items useful to wooden cases must be fumigated

12. Each container contains 6 bags of desiccant, 1kg of desiccant for each bag

photos of packing according to the following template

(Seal No., empty container, loading 1/4, 2/4, 3/4, full, Close the door half full, all closed, nameplate)

Mechanical goods photo shooting and reinforcement

Exhibitions

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.