Paper Core Cutting Machine for Paper Board Tube

$8800≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,FCA,CFR |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | SHANTOU |

Select Language

$8800≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,FCA,CFR |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | SHANTOU |

Model No.: CT-1600A

Brand: SMF

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Bearing, Gearbox, Motor, Gear

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Italy, Viet Nam, Saudi Arabia, Indonesia, India, Thailand, Malaysia, Morocco, Uzbekistan

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Other

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Italy, Indonesia, India, Morocco

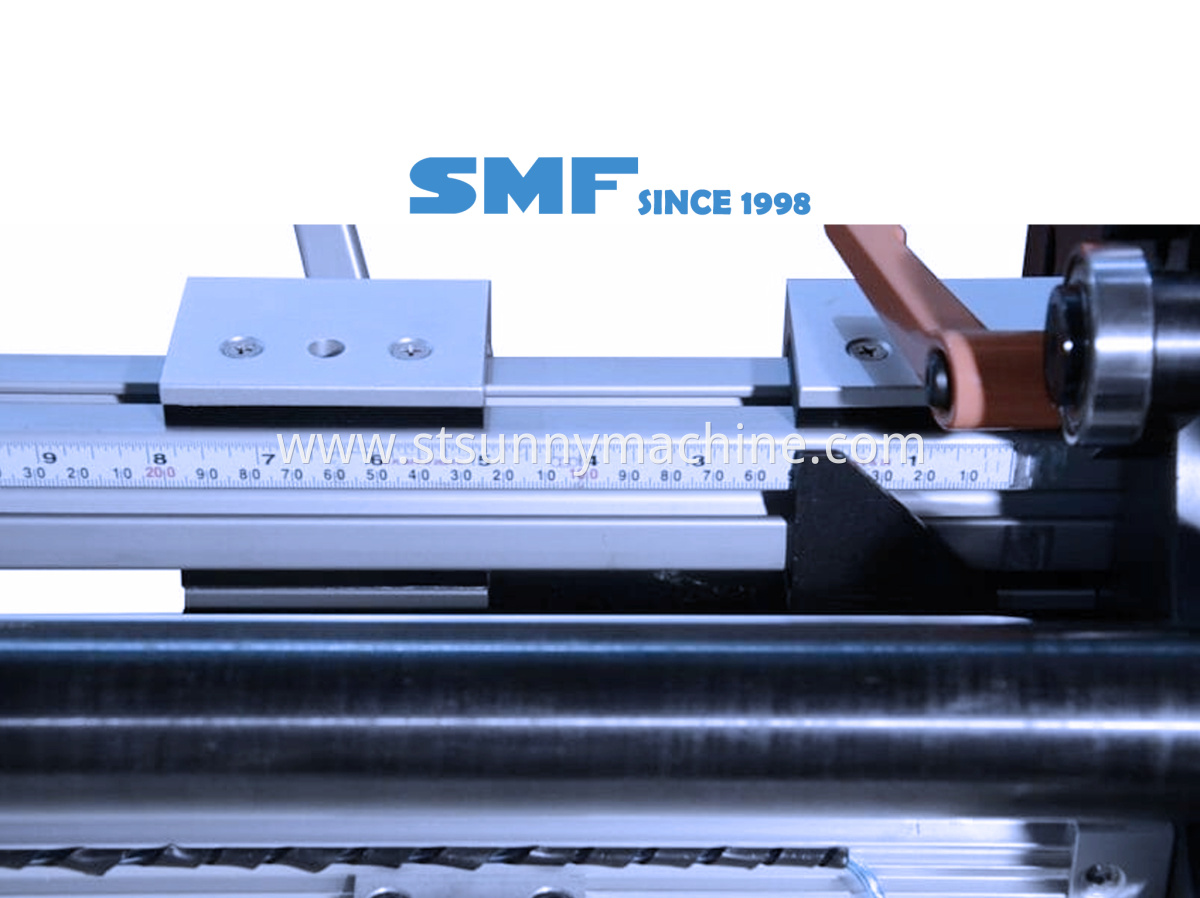

Work Method: Round Knife Cutting

Cutting Mandrels Available For Core ID:: 70mm, 76mm,100mm

Maximum Core Length: 1600mm, 2200mm, 3500mm

Application: paper core manufacturers

Maximum Cutting Speed: 60 cores per minute

Maximum Core Wall Thickness: 20mm

Cut Length Accuracy: +/- 0.1mm

Minimum Cut Length: >4mm

| Selling Units | : | Set/Sets |

| Package Type | : | SEAWORTHY WOODEN OR NAKED |

| Picture Example | : |

|

paper core cutting machine for Paper Board Tube

Paper core cutting machine for Paper Board Tube manufacturer SMF has over 24 years of experience. If you purchase the machine from us, our expertise and rich industry experience will greatly assist you in saving time and energy.

has a predetermined diameter mandrel. The round paper tube is positioned on the mandrel. The Paper tube cutting machine’s blades then engage the cylindrical tube and cut the tubular jumbo roll to predetermined widths. it’s mainly reflected in several aspects, such as automatic paper tube driving, automatic paper tube cutting, etc. Your production efficiency could be improved with these 2 automatic functions.

The servo motor drives the lead screw forward or backward, there is a base connecting to the leading screw, and the paper tube is fixed to the base, so the paper tube keeps the same movement as the lead screw.

Main Technical Parameter information

1. Cutting mandrels available for core ID:3-inch, 6-inch

Dependant on core material (typically equal to core wall thickness)

7. Paper core thickness: 5-10mm

8. Machine dimension: L 2032mm x B457mm x H1092mm

9. Machine weight: 350kg

Our service

You Are Currently Facing The Problem?

A. Without professional technicians, do not know how to choose machine?

B. Do not find the right machine structure to match your currently demand?

C. Found the right machine, but do not have suitable or professional operator to run the lines?

D. No reliable machinery factory can provide a good economic solution for machines?

E. The machinery supplier can not cooperate in time or delivery in time?

F. OEM SERVICE OEM

We have offered OEM service since 1998, and we can make the product with customer’s specific requirements, and can custom the packaging for customer.

We Can Provide You

All project will be serviced by our expertise engineer in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department

We choose the machine structure according to your specific requirements.

We have professional operator dispatch to your esteemed company for training your staff.

We have been served clients all over the world.

We offer quotations within 1-3 days and arrange shipment within 90-180 days.

Specialized OEM Services

1. Components

SIMENS, YASKAWA, MITSUBISHI, MITUSHAHI, E+L, JCTIMES, MERO, HIWIN, ABB and so on

2, Color

Ivory color, the color is determined by you.

3. Size and shape

According to customer requirement and design drawing for reference

4, LOGO

Metal plate or printing

5 packaging

Provide adaptation seaworthy packing, spray antirust paint and reinforce when machine loaded container

Manufacturing process

1. Design

2. Processing

3. Assembly

4. software programming

5. Debugging

6. Shipment

7. Installation

8. After-sale service

automatic paper core cutter machine PC-CT-1600

SMF Paper core cutting machine is a semi-automatic core cutter with simple controls, recipe storage and fast cutting action. With a touch screen HMI, the operator inputs the desired cut lengths, loads the core and presses start. The cores can be cut and offloaded into a box.

Function & Features

1. The long paper-core is automatically cutting into multi-section short paper-core according to the preset specifications

2. Single or multiple cut lengths within same program (up to 5 different widths)

3. The paper-core is cut, and the finished paper-core discharge process is automatically completed

4. Automatic core length measurement

5. The paper-core cutting speed is adjustable

6. Automatic speed setting to suit core outside diameter, finished core discharge process is done automatically

7. The electrical control of the whole machine uses one button only, with a high degree of automation

8. Automatic rotation of blade to extend blade life (optional purchase)

9. Minimal dust generation

10. 7-inch high resolution colour HMI with diagnostics

10. Selector switch for mm and inch

Company Introduction

SMF focus on Innovation Research and Develop Leader Specialize in design and manufacture primary and secondary Slitter & Rewinder machine, CPP/CPE Multi-layer Co-Extrusion Casting Film line and Extrusion Lamiante Coating Machine in China Since 1998.

SMF keep Integrity and pragmatic, keep improving, quality first, customer paramountcy. People-oriented, try our best to do our efforts for the customers' satisfaction, with customers and suppliers adhere to the close cooperation between and close interaction

All project will be serviced by our expertise in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department, so we can offer our clients with our top standard machinery, also we can make all kinds of modifications according to customer specific requirements. Outstanding end-to-end service support. Reliable assistance – around the globe, at all times.

You Are Currently Facing The Problem?

A. Without professional technicians, do not know how to choose machine?

B. Do not find the right machine structure to match your currently demand?

C. Found the right machine, but do not have suitable or professional operator to run the lines?

D. No reliable machinery factory can provide a good economic solution for machines?

E. The machinery supplier can not cooperate in time or delivery in time?

F. OEM SERVICE OEM

We have offered OEM service since 1998, and we can make the product with customer`s specific requirements, and can custom the packaging for customer.

We Can Provide You

All project will be serviced by our expertise engineer in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department

We choose the machine structure according to your specific requirements.

We have professional operator dispatch to your esteemed company for training your staff.

We have been served clients all over the world.We offer quotations within 1-3 days and arrange shipment within 90-180 days.

Specialized OEM Services

1. Components

SIMENS, YASKAWA, MITSUBISHI, MITUSHAHI, E+L, JCTIMES, MERO, HIWIN, ABB and so on

2. Color Ivory color, the color is determined by you.

3. Size and shape

According to customer requirement and design drawing for reference

4. LOGO

Metal plate or printing

5. Packaging

Provide adaptation seaworthy packing, spray antirust paint and reinforce when machine loaded container

CUSTOMIZATION SERVICE

The customer inquire about the certain product according to the demand. After receives the inquiry, we will price the product. Then the corresponding quotation will be sent to the customers according to their request.

Customization process 1

Determine customer needs by meeting, email or telephone. According to the customer`s needs and bargain, we would offer the solution for customer. Our designer will make drawing according to customer needs, or customer shows us what they need, or choose from our available standard machinery.

Customization process 2

According to the solution of first step, our team will prepare drawing accordingly. It includes technical parameters, and all the solutions of machine.

Customization process 3

When everything ready, and after customer finalized project, our team will start to make according to the drawing. Machine production step as below: - requirements finalized by customer – drawing will be provide to customer for confirmation – Initiate to purchase components – assembly in our workshop – any machine processing will be taken photo to customer checking – trial running in our workshop – inform customer come to our factory for official test running acceptance – preparing for shipment – send all documents to customer by DHL

Customization process 4

Our sales team will take photo, videos during loading container and send to customer checking

1. Design

2. Processing

3. Assembly

4. software programming

5. Debugging

6. Shipment

7. Installation

8. After-sale service

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.