PP Meltblown Nonwoven Fabric Machine

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | SHANTOU |

Select Language

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | SHANTOU |

Model No.: SMF-RPM1600

Brand: SUNNY

Application: Nonwoven Surgical Gown

Automatic Grade: Automatic

Customized: Customized

Condition: New

Spinning Resin Suitable For Meltblown: Polypropylene; Melt Index: 1200 ~ 1800g / 10min; Recommended: 1500g / 10min

Finished Fabric Width: 1600nn (Width Of Fabric With Burrs: 1700mm)

Final Fabric Specification: 15-80 G/m2

Screw Specification: Dia. 90×30

Suction Fan Configuration: Flow 20000m3/h, Full Pressure 5000Pa, Power 45KW, Quantity: 1set

Maximum Mechanical Speed: 80m/min

Running Speed: 8~60m/min

DCD (die-to-collector Distance): 100~350mm

Installed Power: About 750KW

Workshop Requirements Of Production Line: L*W*H =≥30m×≥16m×≥8m

| Selling Units | : | Set/Sets |

| Package Type | : | SEAWORTHY WOODEN OR NAKED |

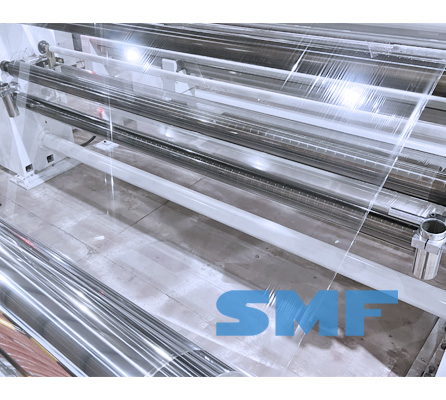

PP Meltblown Nonwoven fabric machine Model SMF-RPM1600

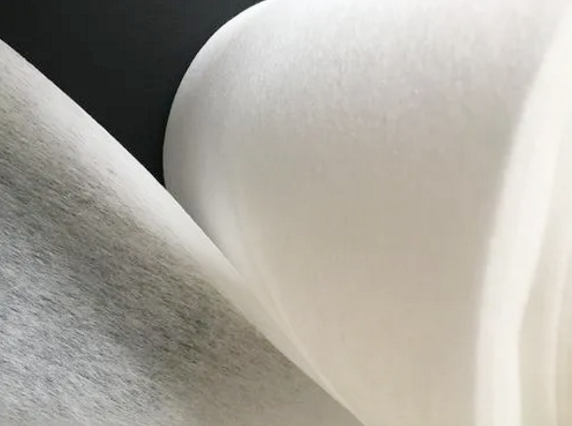

Application: PP Meltblown Nonwoven Fabric Machine is mainly applied to manufacture the kernel material of masks – PP Meltblown nonwoven fabric. Meltblown nonwoven fabric is also known as the "heart" of Medical surgical masks and N95 masks. It is mainly used in medical treatment, surgical gown, protective clothing, disinfection cloth, masks and diapers.

Technical Parameters

1. Spinning resin suitable for meltblown: polypropylene; melt index: 1200 ~ 1800g / 10min; recommended: 1500g / 10min

2. Finished fabric width: 1600nn (Width of fabric with burrs: 1700mm)

3 Final fabric specification: 15-80 g/m2

4 Screw Specification: Φ90×30

5 Suction fan configuration: flow 20000m3/h, full pressure 5000Pa, Power 45KW, quantity: 1set

6 Hot air heating power: 230KW

7 Hot air elongation draught fan configuration: flow 45m3/h, air pressure: 100~110kPa

Maximum mechanical speed: 80m/min

Running speed: 8~60m/min

8 DCD (die-to-collector distance):100~350mm

9. Installed power: about 750KW

10 Workshop requirements of production line: L*W*H =≥30m×≥16m×≥8m

Product application range:

Company Introduction

1. Innovation R&D Leader Specialize in design and manufacture of CPP/CPE Breathable film production Line, Meltblown Nonwoven Fabric Production Line, Extrusion Laminating Coating Machinery and primary or secondary Slitter & Rewinder machine in China Since 1998.

2. Outstanding end-to-end service support. Reliable assistance – all over the world

3. Always at your disposal. Our special customer service team offers reliable assistance for our customers to ensure continuous operation of the SUNNY machines at all times.

4. Experiences since 1998

After Sale-service

- Service is our business

- Non-stop telephone support

- Remote control maintenance system

Client Training Service

- Well-trained & experienced SUNNY service technicians

- Innovative engineeering and the development help our customers to boost their productivity.

Technical Service promise

- Providing Mechanical Electric, Electronic and Process set up.

- Break down analyze

- Always developed for you

- Always specially optimised for your needs

- Our strong design team can draw on extensive experience gained from the hundres of lines we have installed all over the world

5. xpertise Mechanical Engineer Department, Assembly Department, Electrical Automation Department, Training After-sales Department and so on.

6. Top standard machinery can be provided, also all kinds of modifications can be customized according to customer specific requirements.

CPP Cast Film Lines CFL-3500

Cast film products are mainly used in the packaging industry, but technical, medical and stationery films are also important sectors. Indeed, the worldwide market for flexible plastic packaging is predicted to grow steadily within the next years.

Both, film producers and converters, expect high film quality and cost-efficient production. SMF can supply our customers with highly functional machines for their specific market requirements.

|

Auto. Feeding Blender Dosing System

4-component Gain-in weight Batch Blender Dosing per each Extruder.

It is important to ensure the efficient use in every film layer in consideration of that raw material be the main part of the cost for the production of cast films. Multi-components feeding system will be supply according to customer formula and requirements. Gain-in-weight & Loss-in-weight Batch Blender will be provided to client according to client demand.

|

|

Extruder System

SMF Extruder System Frame have a solid steel frame construction

SMF extruders for cast film are designed according to the processing requirements for all the relevant polymers used in this market.

Standard versions with screw diameters from 45 to 250mm is available for selection. Extruders with an L/D ratio of 33 or 35 and bimetallic barrels are powered by energy-efficient, low-maintenance, air-cooled AC drives.

All extruder barrels are heated using advanced heating system, thus retaining the heat in the barrel.

|

|

Connector, Distributor and T-Die Molding system

Different diameter Extruder connector and stainless steel electric heater

Multi-layer Feedblock (Depends on customer demand)

|

|

Feed Block

Technical Advantages

Suitable for processing multilayer and multicolor coextrusion of polymers with similar flow rate and processing temperature.

Conventional feed block structures including: insert type, mandril type,vane type. Besides,dedicated feed block for gradient film and hollow sheet.

Accurate flow channel design assures perfect processing precision.

|

|

Hydraulic Filter

MELT FILTRATION

Effective melt filtration for the removal of impuritieds, unmelted or cross-linked particles is most important. Usually SMF Install hydraulic filters or rotation filters in its cast film lines.

|

|

DIE HEAD

Cast film die series, including dies for producing CPP/CPE film, stretching film, breathable film, barrier film, etc. As a

professional supplier of cast film lines, SMF relies exclusively on reliable partners for its feedblocks and flat dies 3-layer feedblock with three extruders is standard for the production of CPP film, but there is also market demand for structures with five layers and four respectively five extruders. Co-extrusion flat dies with a hanger shape are able to incorporate fixed or variable internal deckling systems, which allows efficient variations of the net film width. Depending on the manufacturer, dies are either chrome- or nickel-plated, but in both cases automatic die control via thermal heated bolts is standard. |

|

BI- Vacuum Chamber, Air blade

and Electronic Edge Pinning System

A combined electrostatic and pneumatic pinning system fixes the film to the chill roll surface and reduces the neck-in. Adjustable

static power and air pressure, as well as easy positioning allow precise pinning and therefore solid contact between the film edges and the chill roll. |

|

Casting Cooling System

The casting station has a significant influence on final product quality. Parameters such as the position relative to the flat die, chill roll temperatures and vacuum box or air knife settings have a direct effect on optical and mechanical properties of the film such as haze, transparency, tensile strength or shrinkage.

The first chill roll has an electro-chemically matted and roughened surface that reduces air entrapment and allows an easy release of the film upon exit. The second and the third (optional) chill rolls have polished and chromium-plated surfaces.

|

|

Online Thickness Gauge Scanner System

In answer to the differing regulations in customer countries and specific product needs, SMF supplies automatic gauging systems either with infrared, X-ray sensors.

SMF places the thickness-gauge unit behind the chill roll to achieve the shortest possible distance from the extrusion die to the measuring point. This results in minimum space requirements and most accurate film thickness regulation.

|

|

Corona Treatment

A corona treatment unit must be installed in order to prepare the films for subsequent offline printing, metallising or lamination processes.

During corona treatment, the film is heated, whereby the amount of heating energy required is contingent upon the speed, raw material and treatment level. Depending upon the design of the treatment station, a driven post cooling roll with a nip roll for additional film cooling can be installed either directly at the corona station, or at the winder inlet.

|

|

TRIM HANDLING SYSTEM

The edges of the film need to be trimmed in front of the corona treater, in order to prevent backside treatment. A final trim is

cut directly at the winder and depending upon the winding system, bleed trims are also removed. The trims are sucked through the grinder to suction then transported to a spiral unloader. This feeds the powder together with virgin material directly to the extruder for the core layer. |

|

WINDING SYSTEM

All these winders have a solid, vibration-dampening steel frame construction, which is able to resist the dynamic forces

generated at high production speeds

Each winder equipped with a large, 12-inch touch screen for winding parameters adjustment and maintenance work

The winder is the basic turret winder for the production of thin cast film mother rolls on 6-12inch shafts with a maximum winding

diameter of 1,200mm. |

|

MDO Unit

For special film applications, SMF integrates an inline MDO into cast film lines.

The modular design of the MDO allows the addition of preheating or annealing rolls. Nip rolls can aslo be installed on every roll

in order to fix the film and to eliminate air entrapment. As an option, the MDO is equipped with an adjustable stretching gap.

The monoaxial stretching process allows to adjust a variety of film properties such as elongation, tensile strength, shrinkage,

stiffness, barrier and optical characteristics. Furthermore, down gauging by stretching represents a growing trend in the film industry. |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.