Duplex shaft slitter rewinder

$68000≥58000Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 58000 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | SHANTOU |

Select Language

$68000≥58000Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 58000 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | SHANTOU |

Model No.: GFTW1280C3

Brand: SMF

Applicable Industry: Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Turkey, Italy, Viet Nam, Thailand, India, Indonesia, Saudi Arabia, Malaysia, Morocco, Uzbekistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Canada, Turkey, Italy, Viet Nam, Thailand, India, Indonesia, Saudi Arabia, Uzbekistan, Malaysia, Morocco

Old And New: New

Species: Slitting Rewinder

Programming Control: Yes

Place Of Origin: China

Warranty Period: 1 Year

Productivity: 300 M/Min

Core Selling Point: Energy Saving

Max. Feasible Width: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Motor, Engine

PLC Brand: Siemens, Mitsubishi

Application: Mechinery&Hardware

Type: High-Speed Slitting Machine

Work Method: Flat Knife Slitting

Structure: Frame Part

Packaging Type: Film

Classification: Ultrasonic Label Cutting Machine

Applicable Process: Process Materials

Suitable Substrates: Film Cutting

Packaging Material: Plastic

Rewind Diameter: 600mm

Thickness: 10--100μm

Rewind Paper-core: 3inches

Slitting Material: CPP,CPE, BOPP, PET, PE, MCPP,Thermal Transfer Film

Unwind Maximum Diameter: 800mm

Effective Width: 200-1300mm

Rewind Width: 50-1300mm

Machine Speed: 500m/min

Whole Machine Power: 380V / 3 Phase, 50Hz About 18KW

Shaft Type: Duplex Shafts

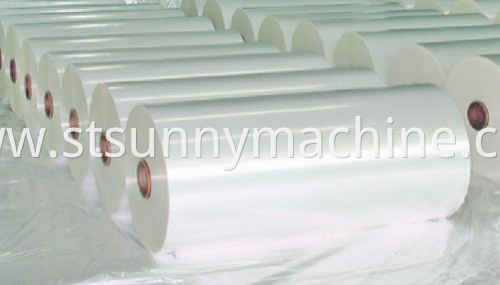

Duplex shaft slitter rewinder

Duplex Shaft Slitter Rewinder Duplex center shaft slitter rewinder machine include center winders and center/surface winders. Primarily for narrow width slitting, the duplex winders handle a broad variety of materials, slit width control, and finished roll quality. We can make customized according to customer's specific requirements and can provide extensive production analysis to make sure the most efficient design is identified.

Main techinical parameters:

Slitting material: CPP,CPE, BOPP, PET, PE, MCPP,Thermal Transfer Film

Thickness: 10--100μm

Maximum Unwind diameter: 800mm

Maximum Rewind diameter: 600mm

Unwind film width: 200-1300mm

Working speed: 500m/min

Whole machine power: 380V / 3 phase, 50Hz about 18KW

Turret slitting rewinding machine

Duplex slitter rewinder machine is mainly use for Plain CPP, VMCPP to meet different applications of our customer. Duplex slitter rewinder Machine Reserved space of corona treatment, customer can add the corona treatment to the machine according to their demand.

|

Slitting Material |

CPP, MCPP |

|

|

|

|

Unwind spec. |

Max. diameter: 800 mm |

|

|

Unwind film width: 200-1300 mm |

|

Working Speed |

300 mpm |

|

Slitting Type |

By Razor slitting |

|

Rewind Spec. |

Max. diameter: 600mm |

|

Min. rewind width: 50mm |

|

|

Rewind paper-core: 3-inch and 6-inch |

|

|

Maximum Rewind width: 1300 mm |

|

|

friction shaft 3-inch and 6-inch, effective width 50-1300mm) |

|

|

Certificates: |

Machine with ECM Certificate |

|

Shipping Delivery & Seaworth Packing: |

90 Days Timely Delivery Time SEAWORTHY PACKING: - Reasonable for repeated packing and unloading; - Reasonable for long-haul stockpiling period; |

|

Service: |

14 months warranty period; Out of warranty service: Video Technical support; Online support; Spare parts; Free on-site service two times a year aperiodicity; Non-stop telephone support, Remote control maintenance system; Client Training Service Technical Service promise Break down analyze |

Applications:

Product advantages:

1. High degree of automation

SMF’s Duplex slitter rewinder machine with automatic constant tension, active unwind and taper tension control, rewind and stop tension maintenance function and Automatic Line and edge web guiding function

2. Hight degree of Human actions

SMF’s Duplex slitter rewinder machine with Siemens HMI, programmable controller (PLC), digital module, and YASKAWA AC Servo Motor drive rewind, YASKAWA servo motor drive traction. Make the whole machine linear speed and three section tension realize dynamic synchronous automatic control, realize soft start, soft stop

3. The electrical control of the whole machine use one control point only, the same command can complete the synchronous automatic control of unwind, rewind and three sections of tension

4. Both Rewind and Unwind are equipped with emergency stop buttons, safe and reliable.

5. Rewind adopts high precision laser lamp Auxiliary paper tube positioning.

6. Electromotion auxiliary unloading system

6. HMI visualization system accomplishes Representation of machine condition

7. Whole machine adopts mechanical structure of easy operation, easy assembly, easy disassembly, easy maintenance

8. Control System

- SIEMENS PLC Programmable controller

- SIEMENS 4DA Extended module

- SIEMENS 12-inch HMI

- SIEMENS Unwind tension setting

CUSTOMIZATION SERVICE

The customer inquire about the certain product according to the demand. After receives the inquiry, we will price the product. Then the corresponding quotation will be sent to the customers according to their request.

Customization process 1

Determine customer needs by meeting, email or telephone. According to the customer`s needs and bargain, we would offer the solution for customer. Our designer will make drawing according to customer needs, or customer shows us what they need, or choose from our available standard machinery.

Customization process 2

According to the solution of first step, our team will prepare drawing accordingly. It includes technical parameters, and all the solutions of machine.

Customization process 3

When everything ready, and after customer finalized project, our team will start to make according to the drawing. Machine production step as below: - requirements finalized by customer – drawing will be provide to customer for confirmation – Initiate to purchase components – assembly in our workshop – any machine processing will be taken photo to customer checking – trial running in our workshop – inform customer come to our factory for official test running acceptance – preparing for shipment – send all documents to customer by DHL

Customization process 4

Our sales team will take photo, videos during loading container and send to customer checking

1. Design

2. Processing

3. Assembly

4. software programming

5. Debugging

6. Shipment

7. Installation

8. After-sale service

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.